In the fiercely competitive microelectronics landscape, advanced radar, electronic warfare, and communication systems are continually pushing the boundaries of frequency, bandwidth, and SWaP (Size, Weight, and Power). To tackle these emerging challenges, the industry must harness the latest advancements in RF, microwave, and mixed-signal technologies.

NEOTech applies its proven expertise, from digital open-architecture boards to custom microwave solutions, delivering trusted high-speed performance for mission-critical systems in space-constrained applications.

NEOTech develops and builds high-frequency, high-speed electronics designed for the most challenging environments—on land, sea, air, and in space. Our electronics and manufacturing engineers utilize the latest techniques to exceed your most demanding size, weight, and power requirements for a variety of technology systems.

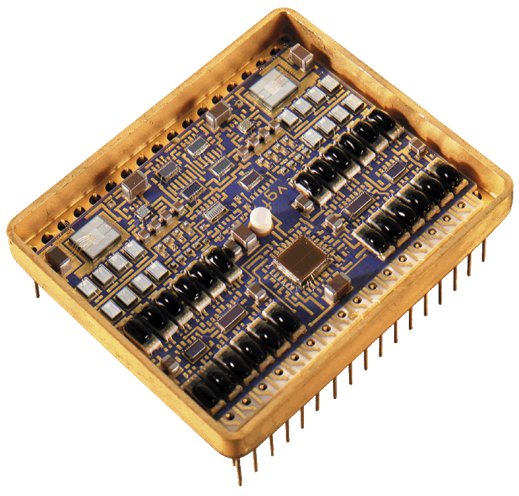

With precision microelectronic assembly, SMT assembly, and mmWave tuning and testing all under one roof, NEOTech is the premier partner for rapid development, launch, and production of cutting-edge technology. As your single partner for prototyping and manufacturing RF Microwave, millimeter wave, digital, and mixed-signal technology, we collaborate with you to create high-reliability systems for aerospace, complex industrial, defense, advanced computing, and next-generation communications applications, from new product introduction to full-system assembly.

NEOTech is Product Realization for Advanced Technology!

Our mission is to collaborate with businesses to design, develop, and produce custom and prototype microelectronics that meet the precise specifications and standards of our clients. With extensive experience in the medical device, aerospace, military, defense, and telecommunications sectors, we have the expertise to fulfill your prototype and production needs.

Our knowledgeable and specialized staff can assist customers throughout the entire microelectronic assembly process, from design to full-scale production. By offering support at every stage of development, we ensure the delivery of high-quality products on time.

In the dynamic microelectronics industry, balancing cost control, risk management, and reliability is crucial. At NEOTech, we excel by leveraging deep expertise in materials, advanced production equipment, standardized processes, and defect-elimination strategies.

NEOTech provides comprehensive assembly services tailored to our clients’ needs. Utilizing state-of-the-art wire-bonding technology, microelectronics packaging, and high-reliability ceramic and laminated substrates, we innovate to meet the evolving demands of the microelectronics sector.

Our wire bonding services feature cutting-edge wedge bonding technology, enabling us to create low-profile interconnects perfectly suited for microelectronics applications. Whether for small-scale or large-scale production, our wire bonding facility ensures rapid turnaround times to meet all your production requirements.

With more than forty years of expertise in high-reliability hybrid and RF technologies, NEOTech has established itself as the largest provider of microelectronics assembly services in North America. We offer a comprehensive array of services encompassing the design, development, and manufacturing of microelectronic assemblies, specializing in microwave electronics and circuits. Our dedicated teams are committed to delivering technical support and advanced testing for microelectronic assemblies, ensuring superior quality and reliability for our customers.

Offshore manufacturing strategies are collapsing under the weight of rising tariffs, unpredictable logistics, and quality control challenges. NEOTech offers a smarter path forward—with trusted U.S. and Mexico-based electronics manufacturing services built for resilience, agility, and excellence.