NEOTech bridges the gap between product innovation and flawless production, helping leading OEMs in the High-Tech Industrial, Medical Device, and Aerospace markets bring complex designs to life with precision, scalability, and reliability.

Many OEMs excel at what they do best—identifying customer needs, conceptualizing breakthrough products, and crafting strategies to capture market share. Yet even the most visionary companies often encounter the same obstacle: transforming a great design into a manufacturable, testable, and reliable product.

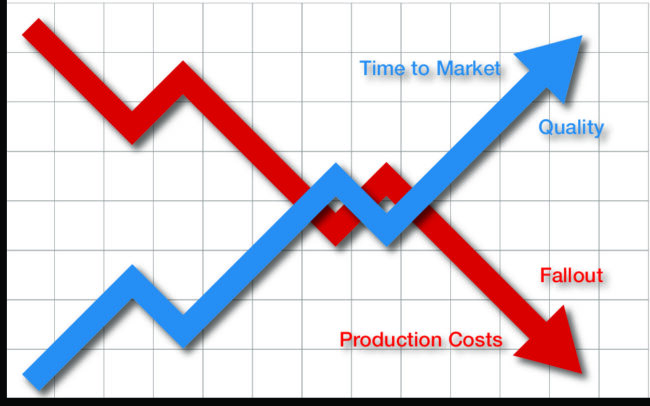

Designing a high-performance product doesn’t automatically make it ready for production. Without the right engineering insight, small design inefficiencies can lead to high fallout, long test cycles, and supply-chain challenges that threaten schedules and profitability.

Designing a high-performance product doesn’t automatically make it ready for production. Without the right engineering insight, small design inefficiencies can lead to high fallout, long test cycles, and supply-chain challenges that threaten schedules and profitability.

That’s where NEOTech steps in—not as a vendor, but as a partner with the engineering and manufacturing depth to transform innovation into consistent production success.

OEMs drive product conception. NEOTech drives product realization.

Our teams specialize in every stage of the electronic manufacturing value stream—from Design for Excellence (DFX) to final assembly and testing. We ensure each design isn’t just intelligent, but also optimized for manufacturability, fabrication, and testability.

Design for Manufacturability (DFM): We collaborate early with OEM engineering teams to reduce assembly complexity and ensure smooth production ramp-up.

Design for Fabrication (DFF): We help align PCB design with fabrication processes to eliminate costly iterations.

Design for Test (DFT): Our engineers develop efficient, reliable ICT and functional test strategies to minimize production fallout and ensure product reliability.

With NEOTech’s engineering support, OEMs can confidently move from concept to production knowing their designs are robust, manufacturable, and built for success.

At NEOTech, manufacturing excellence isn’t defined by size—it’s defined by capability. As a Tier 2 EMS provider, we combine advanced electronic contract manufacturing technology, rigorous process control, and deep supply-chain expertise.

Our teams manage the complexity so our customers can focus on innovation:

Advanced PCBA and CCA assembly through state-of-the-art SMT and through-hole lines.

Comprehensive sub-assembly and final box-build integration, delivering ready-to-ship products.

Fully traceable quality systems, certified to ISO 9001 for industrial markets, ISO 13485 for medical devices, and AS9100 for aerospace applications.

Dedicated supply-chain management, providing complete visibility while mitigating risk and ensuring on-time delivery.

This isn’t outsourcing—it’s collaboration. OEMs trust NEOTech because we extend their team with proven expertise across the entire electronics manufacturing process.

With manufacturing locations in Fremont, CA, and Juarez, MX, NEOTech offers OEMs the flexibility to scale efficiently while maintaining close technical collaboration.

Fremont sits in the heart of Silicon Valley, where engineering agility meets rapid prototyping and high-mix precision builds.

Juarez delivers large-scale, cost-effective production capacity with exceptional process discipline and logistics coordination.

Together, these facilities create a unified production ecosystem—one that allows OEMs to move seamlessly from pilot builds to full-rate production without losing control, quality, or visibility.

By combining engineering collaboration, DFX expertise, and advanced electronic manufacturing services, we ensure every product is built for performance, reliability, and end-user confidence.

When your reputation depends on quality—and your customers depend on your products—partner with the team that transforms innovation into manufacturing excellence.

Because at NEOTech, we don’t just build products.

We build the confidence behind every great idea.

Steve Bates, NEOTech Marketing Manager – November 2025