From component shortages to global logistics hurdles and stringent product reliability requirements, OEMs must depend on partners who can manage the entire process—from supply chain to final system testing—with precision, transparency, and trust.

At NEOTech, our Fremont, California, and Juarez, Mexico, facilities represent the model of what a modern electronic manufacturing service partner should be. Both locations combine scalable capacity, deep engineering expertise, and a people-driven culture of continuous improvement to empower OEM success.

An OEM’s production schedule is only as strong as its supply chain. Unplanned material shortages, late deliveries, or lack of visibility can compromise time-to-market and  profitability. The ideal electronic contract manufacturing partner must provide complete transparency while absorbing the day-to-day burden of managing complex global logistics.

profitability. The ideal electronic contract manufacturing partner must provide complete transparency while absorbing the day-to-day burden of managing complex global logistics.

NEOTech does exactly that. Our customers benefit from full visibility into material status and delivery timing—without having to handle any of the complexity themselves. Fremont’s position in the heart of Silicon Valley provides immediate access to a robust local supplier network, enabling rapid component sourcing and shorter lead times for critical printed circuit board assembly (PCBA) builds.

Meanwhile, the two Juarez facilities have developed a reputation for logistics mastery—seamlessly managing high-volume programs with efficient cross-border operations and well-coordinated material flow. The result is reliability and peace of mind: OEMs can focus on innovation, while NEOTech ensures every component arrives exactly where and when it’s needed.

For products that power aircraft systems, industrial automation, and life-saving medical devices, quality is not negotiable. OEMs must seek partners with a proven Quality Management System (QMS) and industry certifications that guarantee consistency and compliance.

NEOTech’s Fremont facility is certified to ISO 9001 and ISO 13485, reflecting its readiness to support both High-Tech Industrial and Medical Device OEMs that demand exceptional process control and traceability. Our Juarez facilities are certified to ISO 9001, ISO 13485, and AS9100, expanding their capability to include large-scale Aerospace OEM programs that require rigorous quality oversight and documentation.

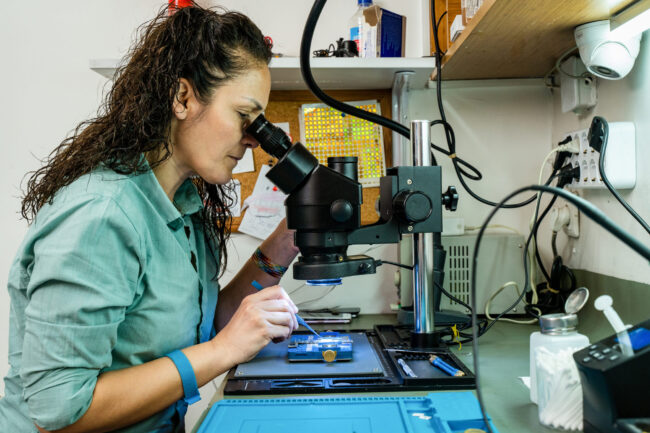

Every PCBA, circuit card assembly (CCA), and printed circuit board assembly produced in our facilities undergoes meticulous inspection and test validation. NEOTech’s QMS is not simply a certification requirement—it’s an organizational mindset. Every technician, engineer, and program manager takes ownership of delivering zero-defect quality, every time.

Modern OEMs need more than a basic assembly line. They need a partner that can provide a complete electronic manufacturing service—from board-level assemblies to fully tested systems ready for deployment.

NEOTech’s Fremont and Juarez operations deliver this end-to-end capability. Both sites offer advanced SMT and PTH PCBA production supported by extensive engineering resources for ICT (In-Circuit Test) and custom test-strategy development. These capabilities ensure every printed circuit board assembly and CCA meets exact performance specifications before integration.

Beyond PCBAs, both locations also excel at sub-assembly and final box build assembly. NEOTech provides full functional testing for these higher-level builds, ensuring system-level integrity and seamless product integration for OEMs. This vertically integrated approach reduces supply chain handoffs, accelerates production ramps, and maintains consistent quality from first prototype through full-scale manufacturing.

NEOTech’s Fremont facility provides the agility OEMs need for rapid prototyping, engineering collaboration, and new product introduction (NPI). Its close proximity to Silicon Valley’s design and innovation centers enables direct interaction between OEM and NEOTech engineering teams, dramatically shortening design-to-manufacturing cycles.

In Juarez, NEOTech’s two large-scale facilities bring unmatched scalability. With expansive production space, high-volume SMT lines, and robust quality systems, they support both early-stage programs and mature products that require consistent throughput. This scalability ensures OEMs can maintain flexibility as products evolve—without the disruption of transferring programs between suppliers.

Both Fremont and Juarez specialize in manufacturing highly complex circuit card assemblies and system-level integrations, combining advanced process automation with human expertise to achieve the highest standards of reliability and repeatability.

While equipment and certifications are vital, it’s people who ultimately drive quality and innovation. NEOTech’s culture of empowerment encourages employees at all levels to identify improvements, propose solutions, and act in the best interests of the customer.

Choosing the right electronic contract manufacturing partner is about far more than cost—it’s about trust, transparency, and technical depth.

At NEOTech, our Fremont and Juarez facilities embody the qualities OEMs depend on:

Transparent and expertly managed supply chain and logistics

Certified, robust Quality Management Systems

Complete manufacturing capabilities from PCBA to final box build

Advanced test strategy engineering resources for ICT and functional testing

Scalable production for High-Tech Industrial, Medical Device, and Aerospace OEMs

A culture of continuous improvement that drives long-term success

NEOTech delivers confidence at every level of production—ensuring that every board, assembly, and finished system leaving our facilities performs exactly as our customers intend. Because for NEOTech, manufacturing isn’t just about building products—it’s about building trust.

Steve Bates, NEOTech Marketing Manager – October 2025